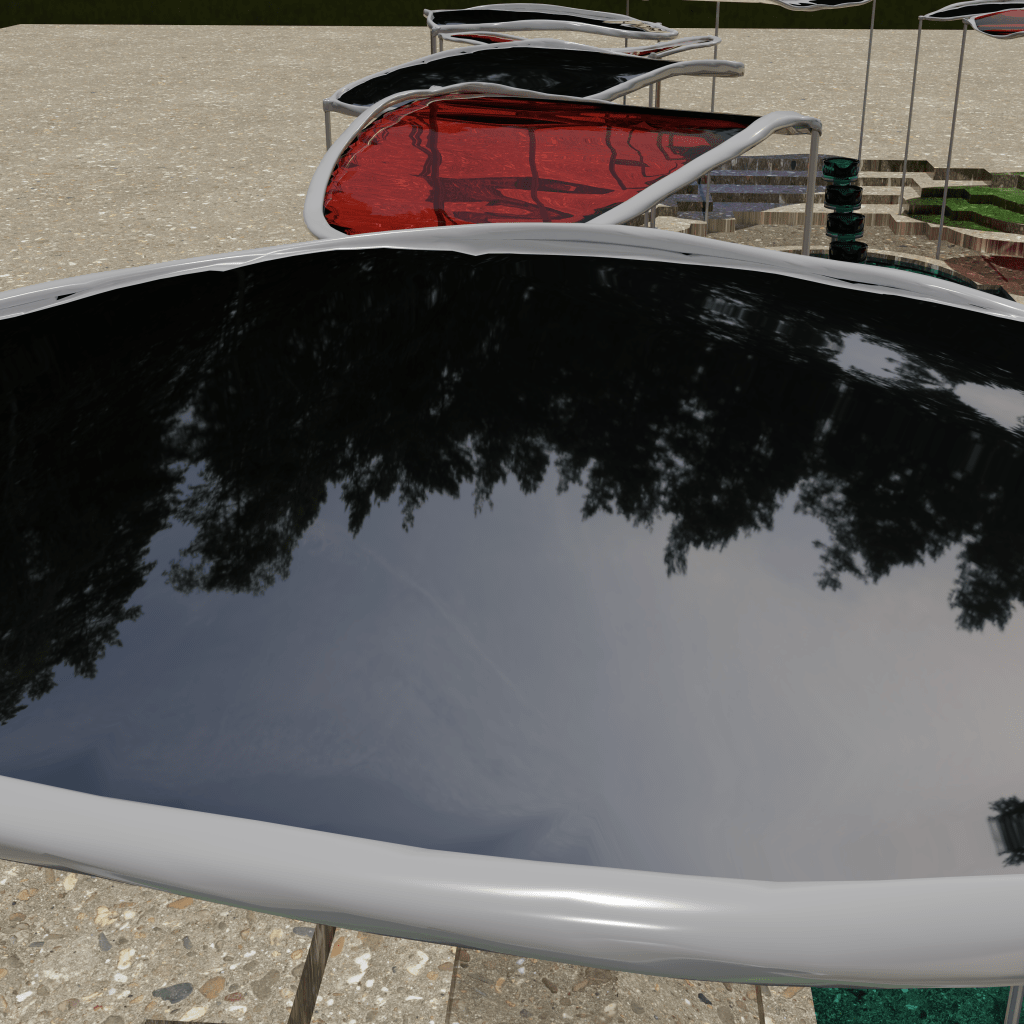

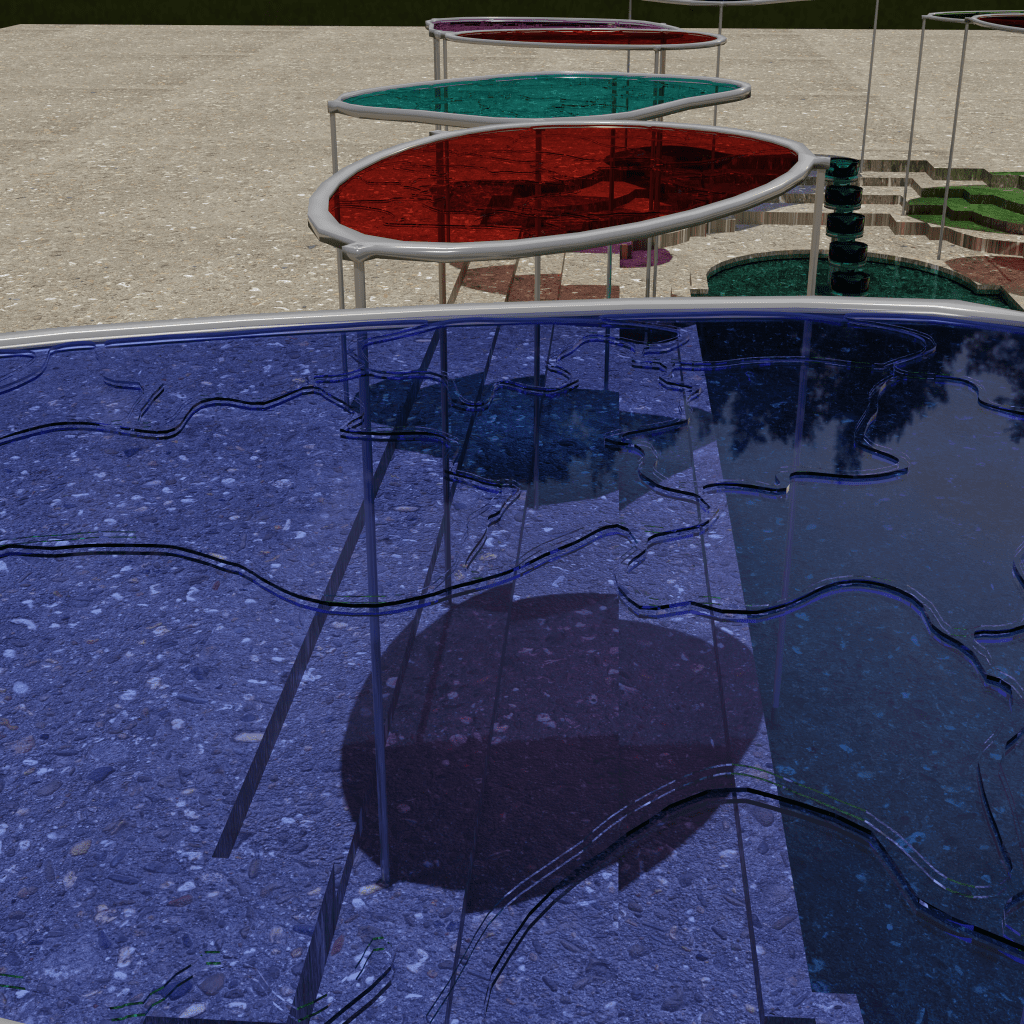

3D model what it would look like if the support bars aren’t vertical but horizontal (linked with each other) supported by a few support bars

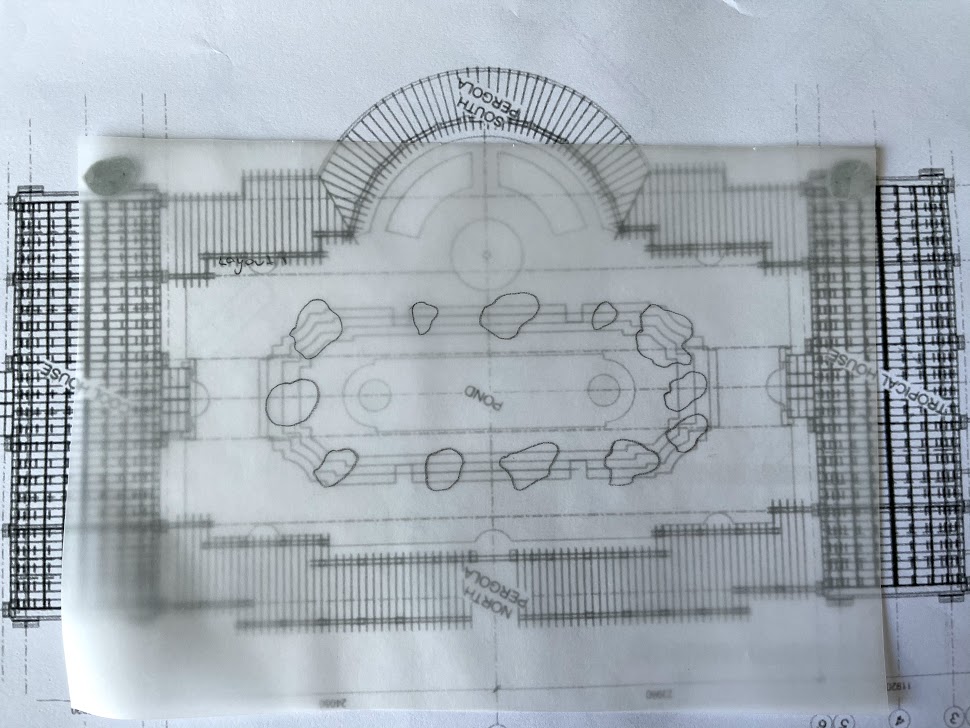

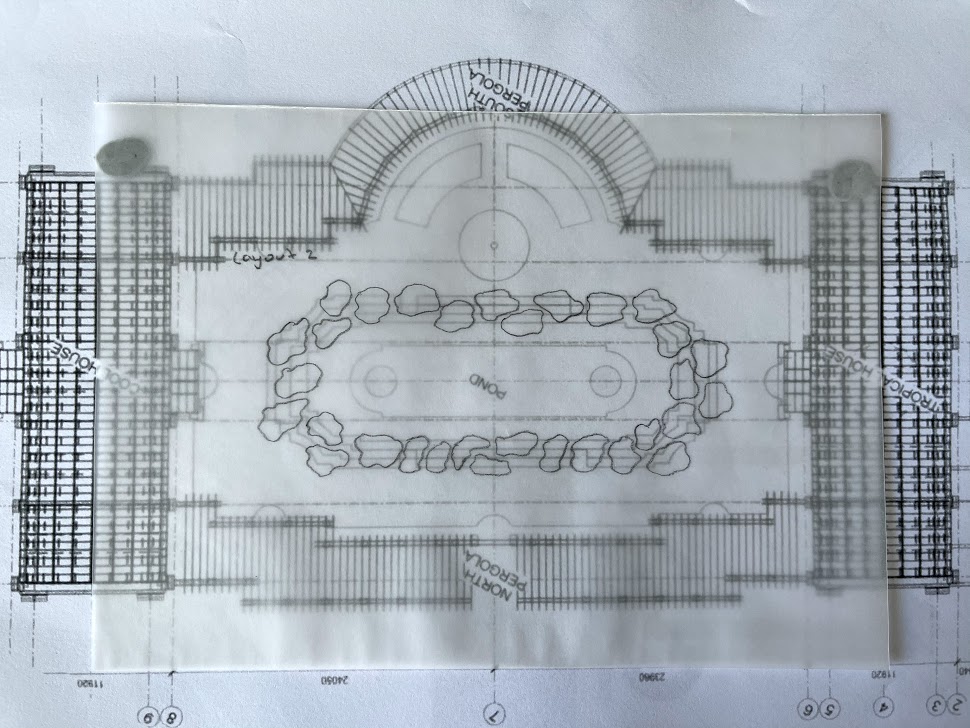

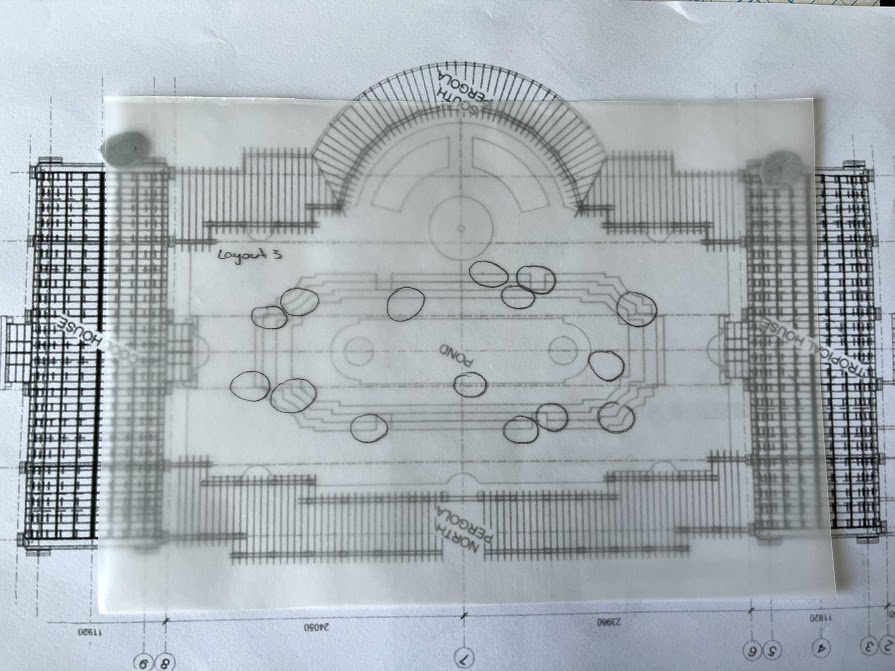

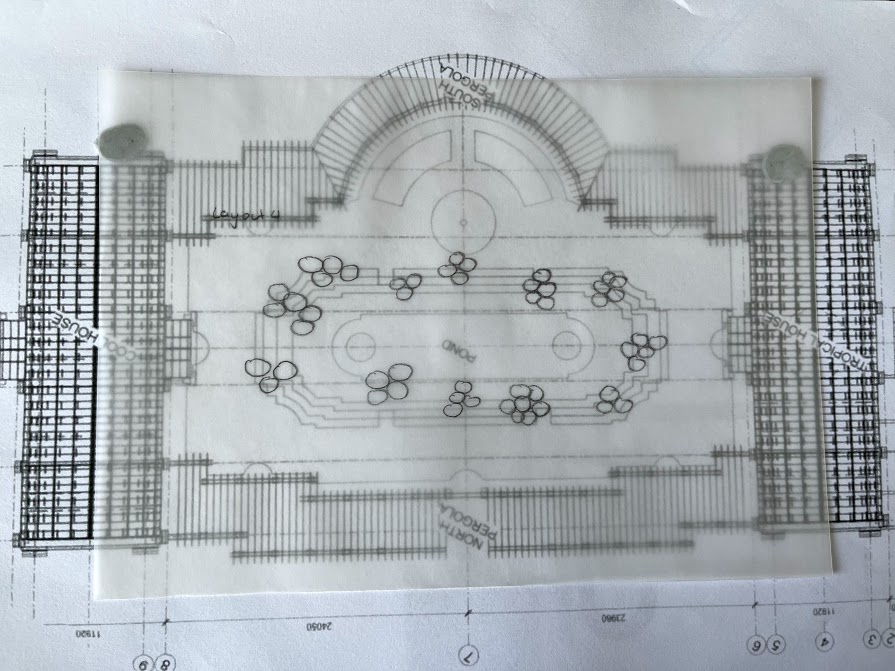

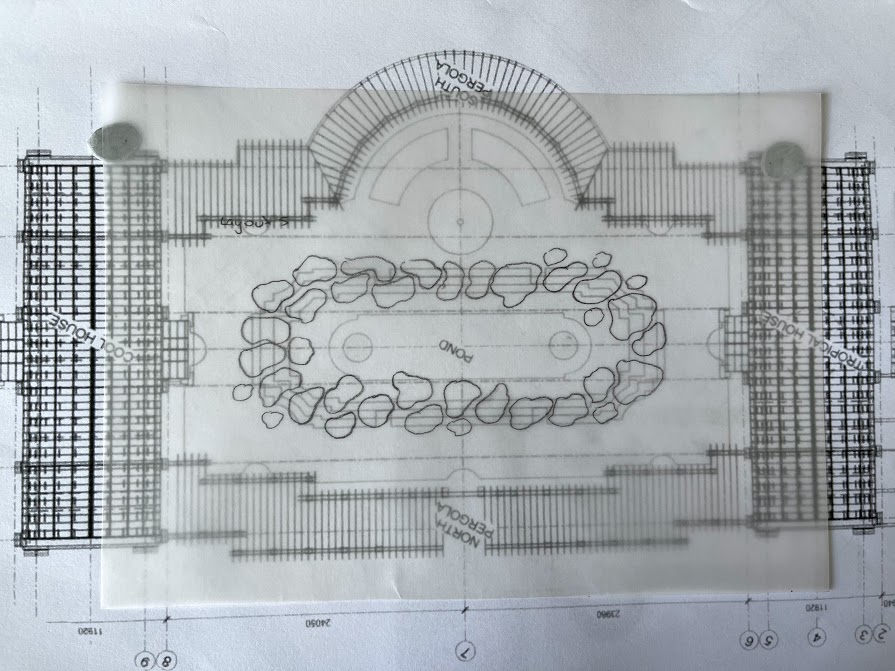

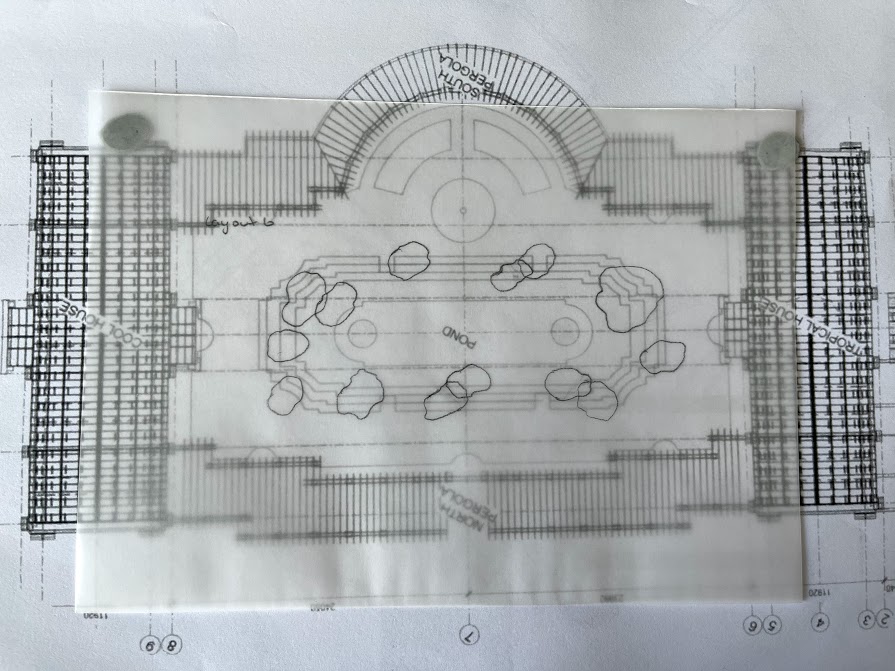

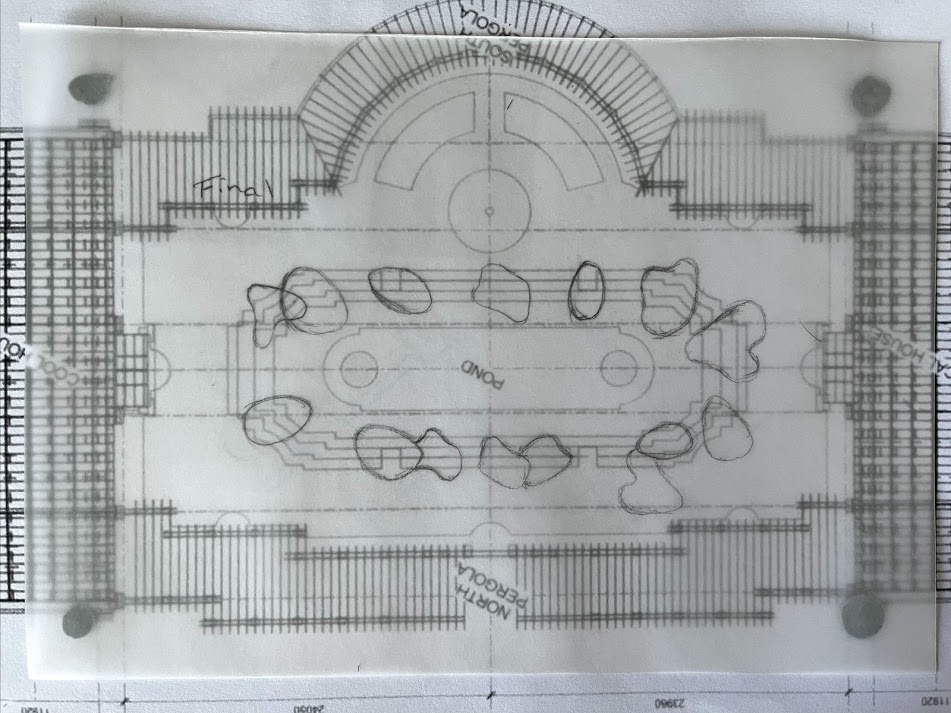

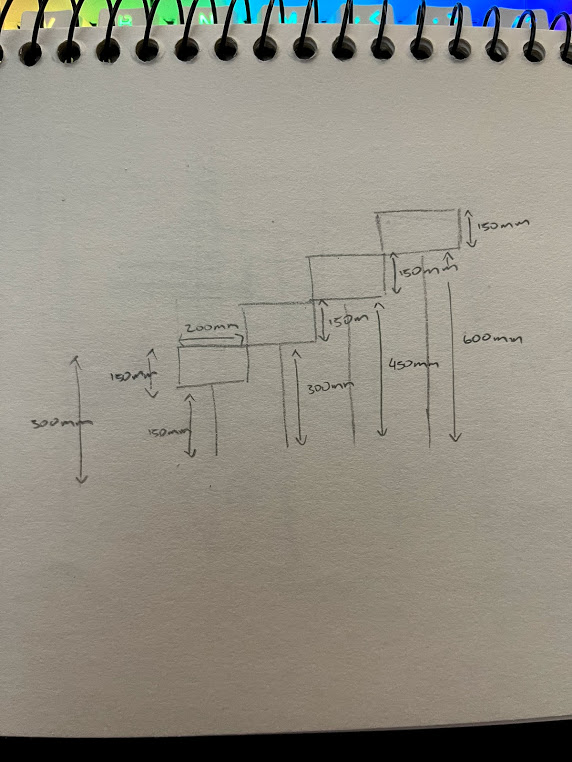

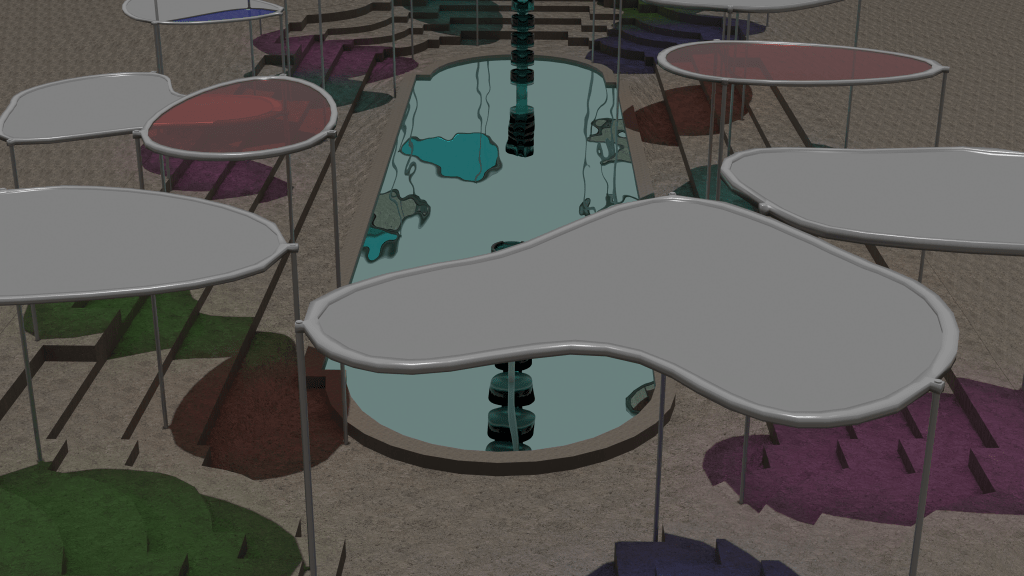

Layout plan

For my final layout I quite like design 1 and 6 this is purely because since the two glasshouses are identical and symmetrical as well as the fountain on each side of the pond I figured that the idea for the coloured glass shelter should be inspired by lilypads (overlapping, different sizes, random placement, and unusual shape)

For the final layouts I am leaning towards the saying “Less is more”, this is because it’ll look overcrowded with all the support poles on the courtyard. For the shelters they’ll be 15 of them

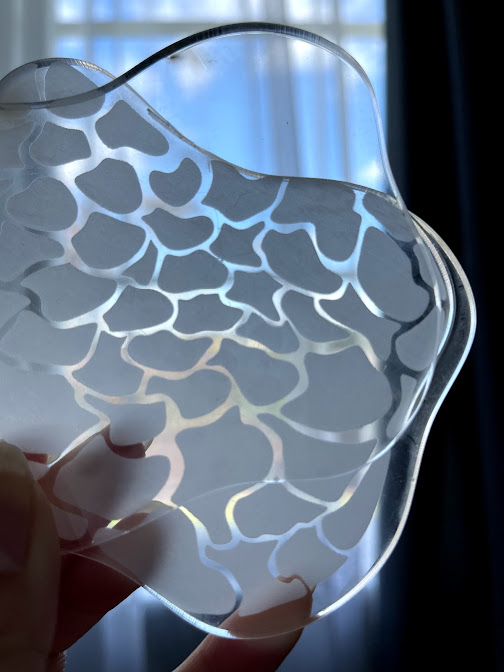

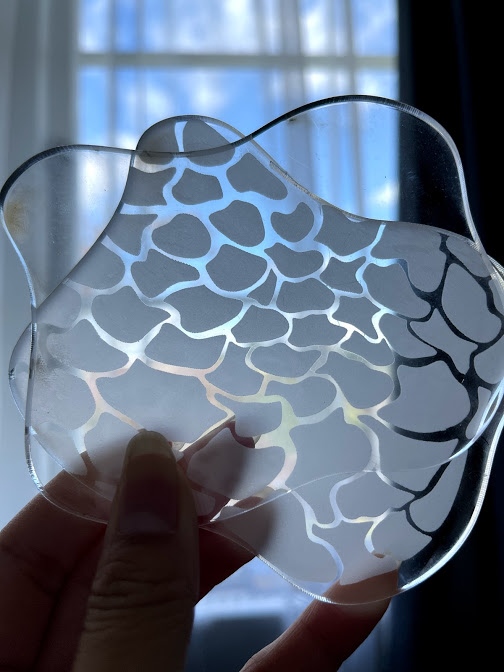

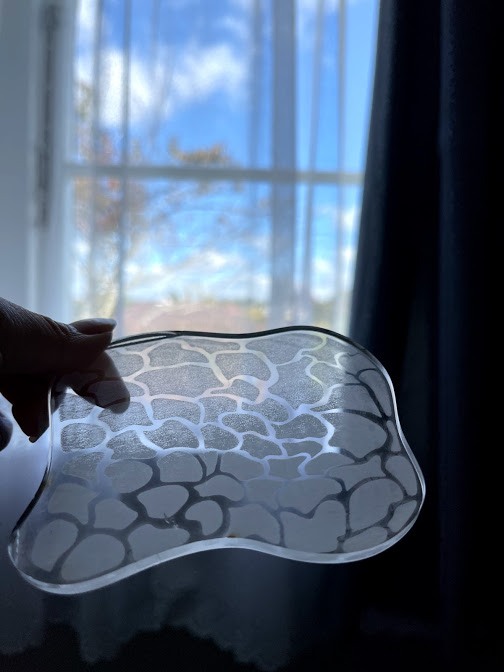

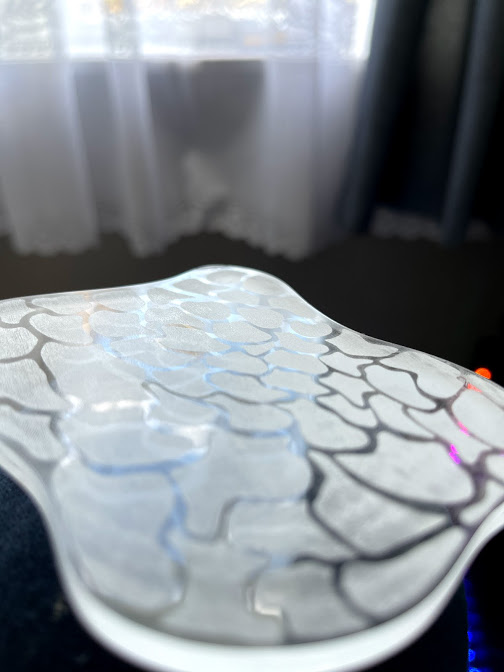

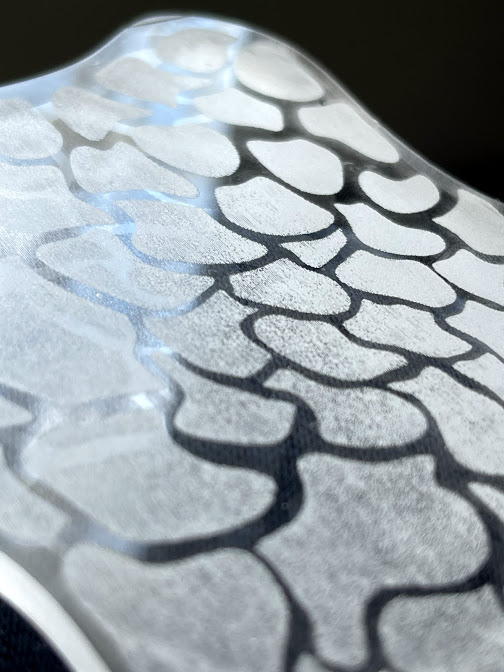

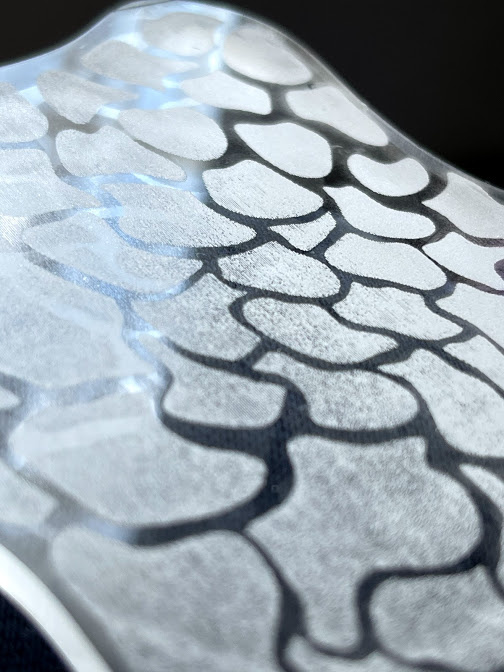

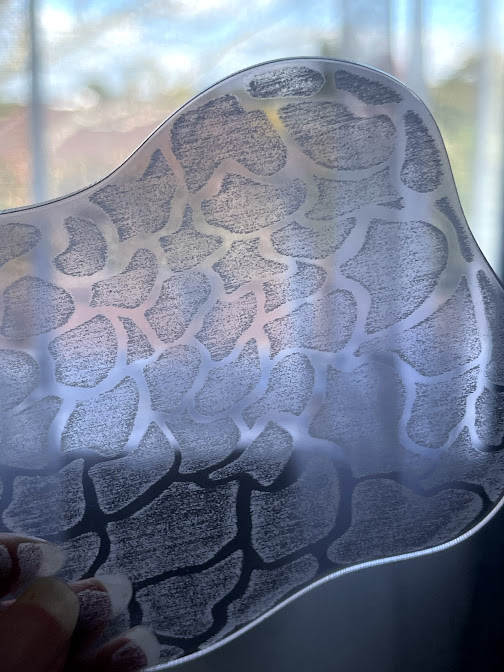

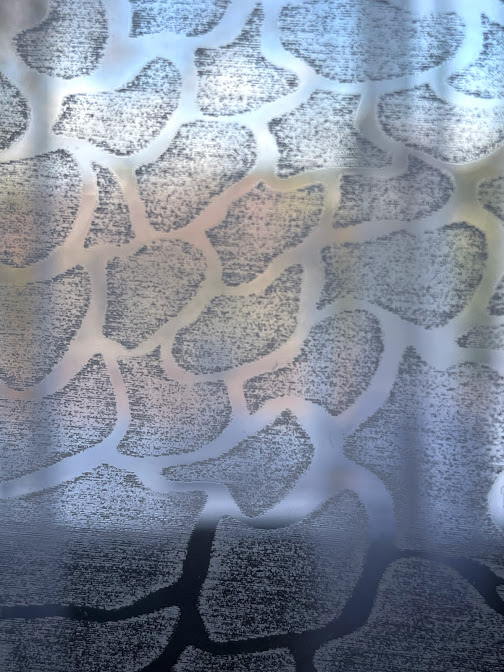

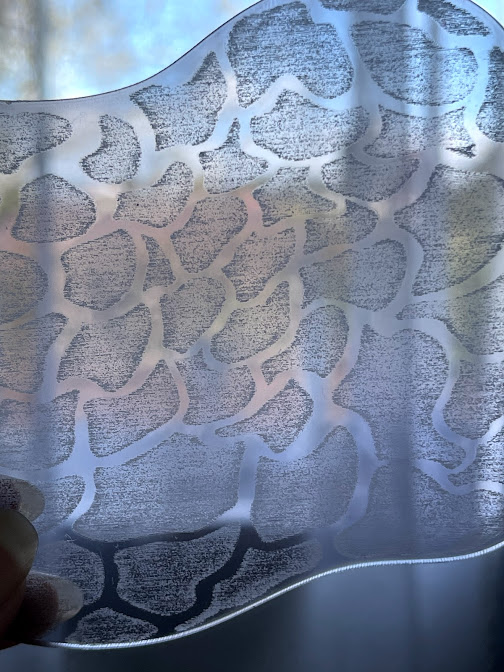

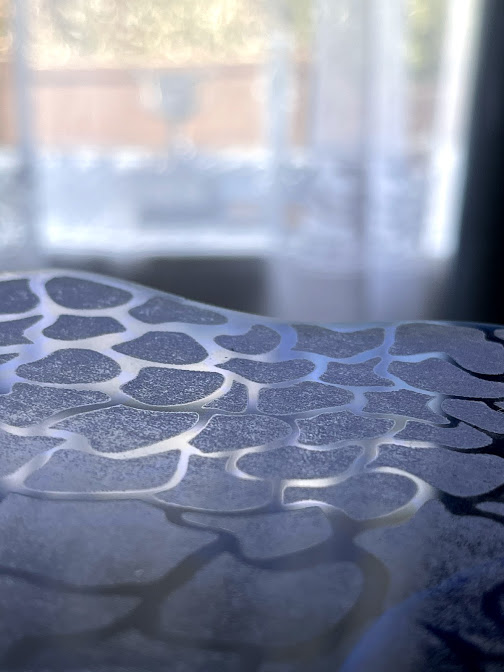

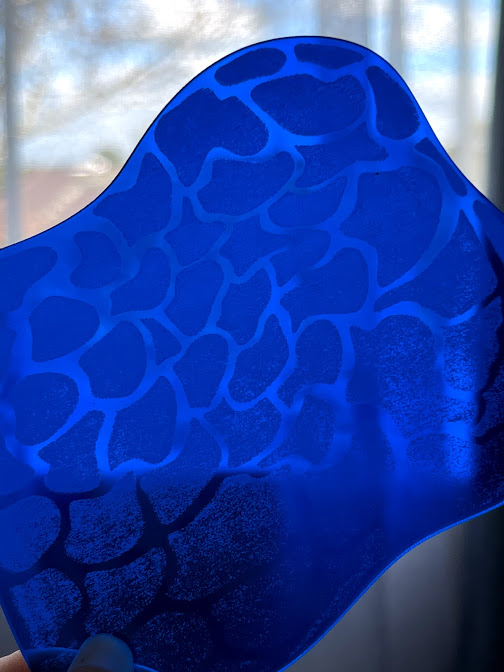

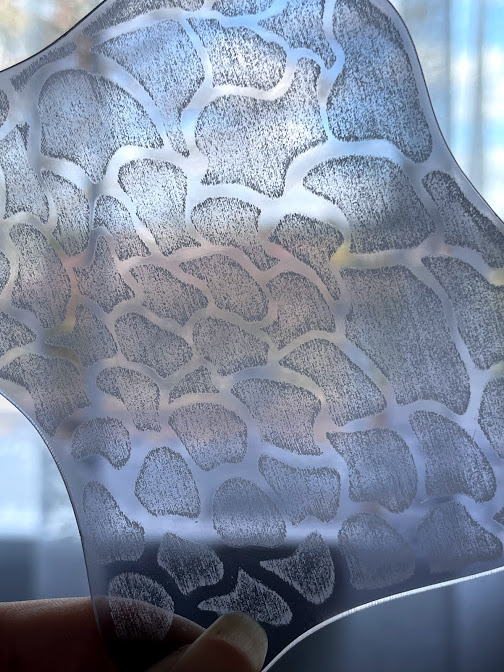

Laser cut prototype testing

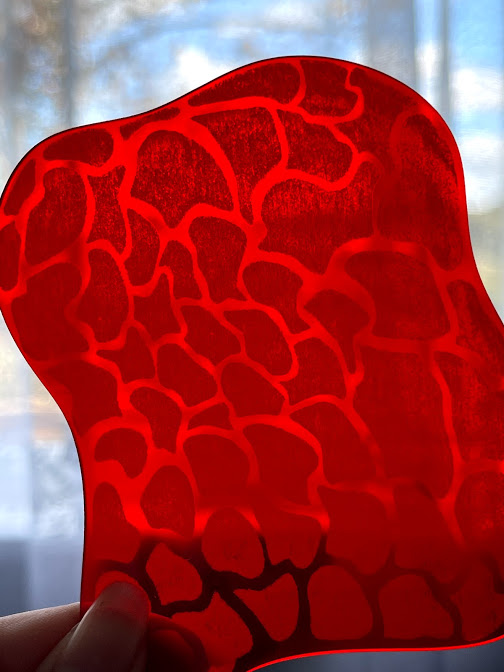

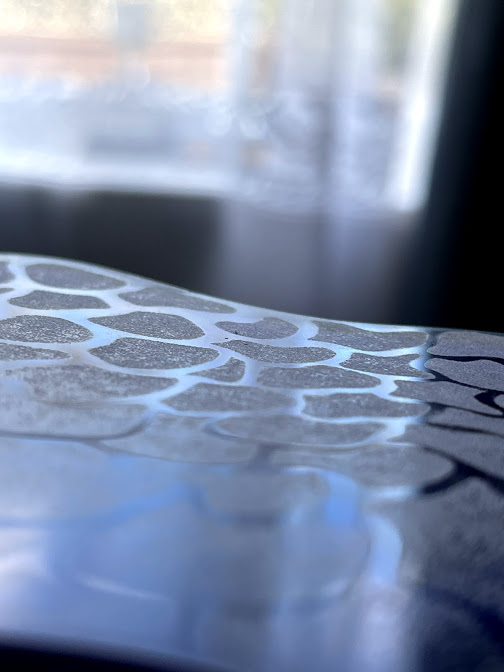

For a prototype of my design proposal I used coloured acrylic sheets to get the idea what this may look like in person I made this by 100mm to 60mm

As these were an experiment prototype I had to use scrap materials from the lab at WM level 3. For acrylic sheets materials it comes with limited colour palette

For the raster etching design I used a simple scoria design just to see what the glass might look like in person if the actual glass was designed.

Colour palette

These are the colour palettes experiment I have chosen from using the photos I have taken of the site

After looking through all the photos I have taken I realised that I quite like the bright pastel colours as it pops out more and since the courtyard needs colours pastels would be quite fitting to the site itself

In conclusion I have choosen to go with colour palette one, as i’m pretty sure pastel colours will pop more when put into the site as from visiting the site i’ve noticed that the only colours that can be found in the site (Wintergardens – two glasshouses) are greenery, while flowers are outside the site. Hence to why I plan on using the first palette as it has the colours that the site doesn’t have to make the courtyard more appealing and colourful to attract more people into the site.

Color in Marketing

Color is light and light is energy. Color can stimulate and excite us. It can make us feel happy, tranquil… or even depressed. We experience the psychological effects of color all day. It’s subconscious, yet effective.

In addition to identifying brands, colors can actually draw us to certain products. Marketers know this, and they use it to their benefit.

Studies show that red can actually increase our pulse, blood pressure and adrenaline, hence the red Nike swoosh. When combined with yellow, red can make us feel hungry. McDonald’s, anyone? Orange makes us feel happy and excited and is a great way to entice us to buy something. Yellow makes us think of sunshine and can be used to grab our attention in a comforting way.

Spring is the perfect time for marketers to target our emotions. You can’t help but feel happy. It’s a time of rebirth, renewal, and rejuvenation.

Pastels are less saturated than primary colors, making them feel light, soft, and calming. For spring, they work well with neutral colors to create a feeling of earthiness and sophistication.

More ideas (glass and metal)

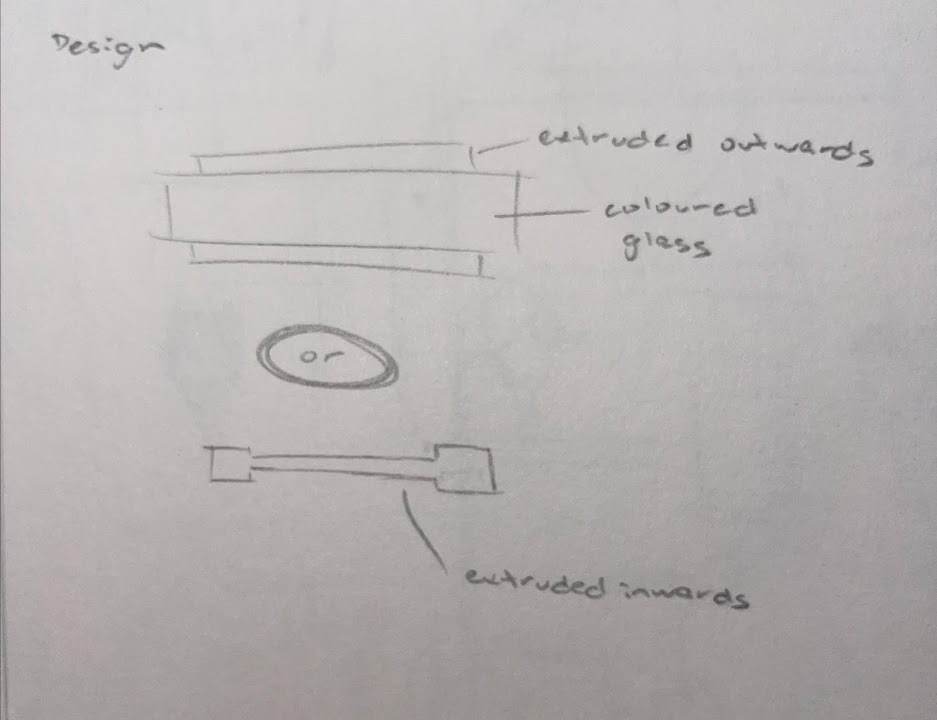

Instead of flat surface glass shelter what if it had some extrusion to it??

Instead of raster etching onto it for the design what if the other way to hold up the glass (metal) has its own design to it

Square support poles -> Cylinder support poles

Rafik’s Feedback

Variation onto the glass shelter (tilted, why is it flat, not all on the same axis,

Explain to why I choose the prototype colours

Explain where I got the colours from from the colour palette’s I created

Look into other designers designs

For final render make sure the glass creates the coloured shadows

Glass pavilion petal designs

K sejima pavilion

Keep developing

Nice variation/ using my own design onto the glass

Skinny poles, weirdly shaped poles

Metal or Steel??

Image below would be great if i can capture my 3D model like that

Other designers inspo

Kazuyo Sejima pavilion (An Aluminium Canopy Floats Among the Trees)

Amanda Levete’s (Tree canopy-like MPavilion opens in Melbourne)

Amanda Levete’s tree canopy-like MPavilion opens in Melbourne

Dan Graham (Pavilion/Sculpture for Argonne)

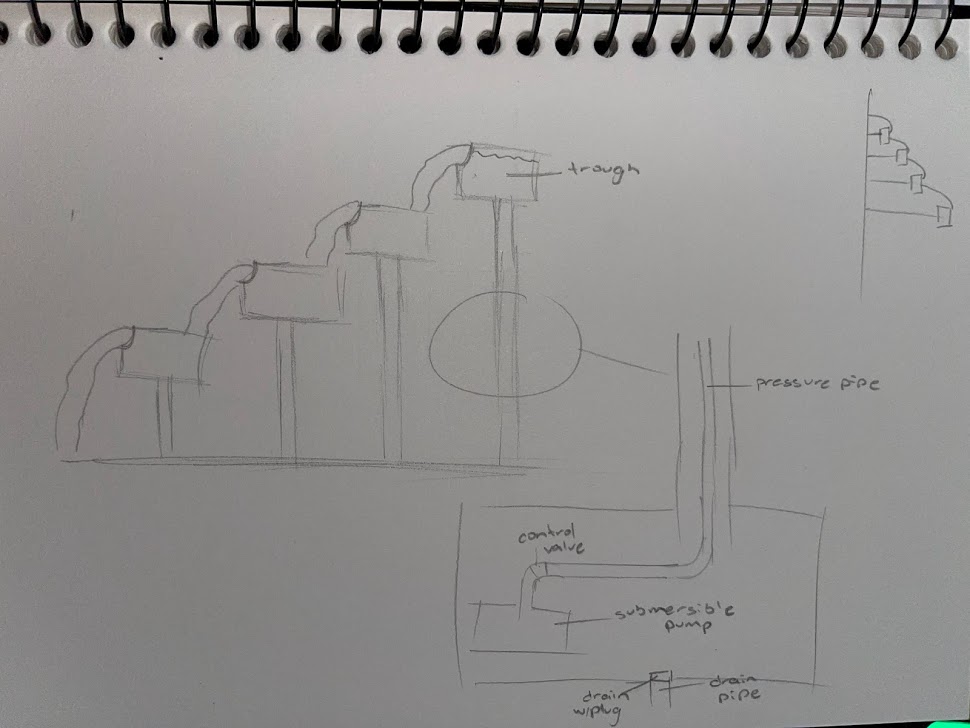

Fountain

How the fountain works

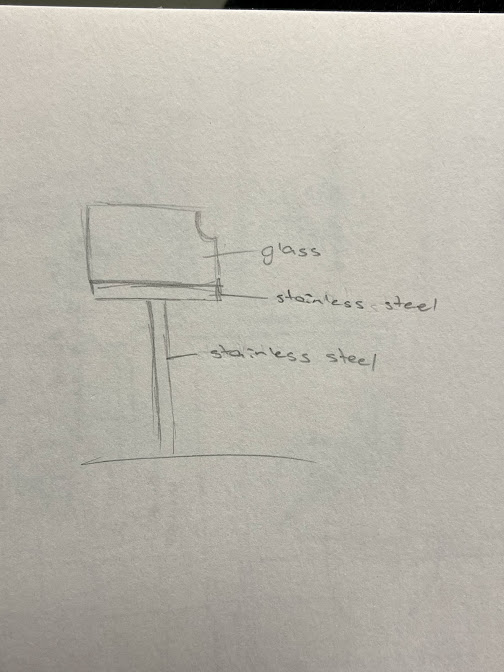

Metal or Steel

Difference between metal and steel

The main difference between steel and metal is that steel is an alloy made from iron metal, and metals are elements naturally present in the earth’s crust, and mined out from various parts of the world. Metals are nonmagnetic, ductile and non-corrosive elements with high resistance to tarnishing. Metals are also safe, and have hygienic properties; they are present in the biological system of the human body, and not harmful when implanted.

Steel is made by adding a controlled amount of carbon to iron. Different metals are added to make almost sixty grades of steel alloys. For example, chromium is added to steel for making stainless steel. Contrary to other metals, steel is known for its strength and fatigue life. It can bear tons of loads for a long time compared to other metals.

Metal ores need to be refined before use. The impurities called slag, or other metals are removed. Then they are combined with other metals to produce more strength and qualities. Metals are plated to produce more shine and stability, such as brass is nickel-plated, or gold-plated silver. Steel is a compound of iron and carbon, made in furnaces. Steel has viscosity, and shrinks when cold. In extreme weather, conditions like cold temperatures can affect steel to brittle but metals can withstand minus temperatures. Metals have the attributes of luster, ductility and malleability, that make their application in various industries very easy. They are used for making coins, jewelry, weaponry, surgical implants, industrial products, household products, engineering and construction, architecture designing and decorative products. Steel is used for making strong structures, tools, auto vehicle bodies and other components, building material, bridges, ships, guns etc. Steel is corrosive, and can rust if carbon is present in a high content. It is magnetic, and not as powerful a thermal or electrical conductor as a metal. Steel is made hygienic by adding metals, for example chromium. Steel is a man-made element, and much cheaper than gold, silver, aluminum or other metals. Metals are expensive, and some of them are regarded as monetary objects, like gold and silver.

Metals have high melting or freezing points; that means the freezing point of a metal is same point as its boiling point. The boiling point of steel is 3000 degrees. In this modern era of technology, nearly all metals that are found are either alloys or combined with other metals to improve their strength, hardness and resistance powers. Pure metals are not affordable to be used widely and economically. Steel is economical, and used for its weight bearing quality in numerous ways.

Summary:

1. Steel is not a metal, but an alloy of iron, and fabricated in furnaces.

2. Metals exist naturally in the crust of the Earth, and are mined out of the ground.

3. Steel is strong, and made for structures used for the building of houses, sky scrapers, ships or guns.

4. Metals are malleable, ductile and used for making jewelry, decorative products and surgical implants.

5. Steel can rust, and is magnetic. Metals are anti corrosive and nonmagnetic, and are high thermal and electrical conductors.

Read more: Difference Between Steel and Metal | Difference Betweenhttp://www.differencebetween.net/object/difference-between-steel-and-metal/#ixzz6uPhVvT4p

In conclusion I decided to use stainless steel for my material as to prevent it from staining over time

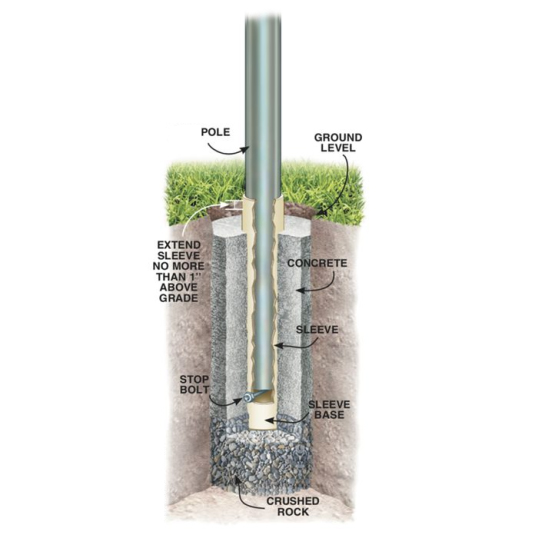

How the shelters stands up

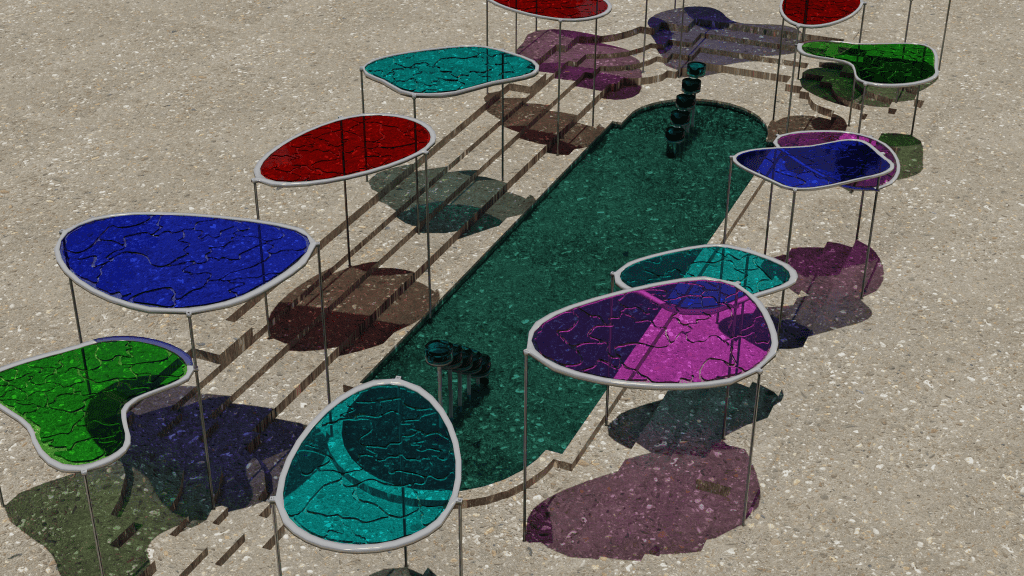

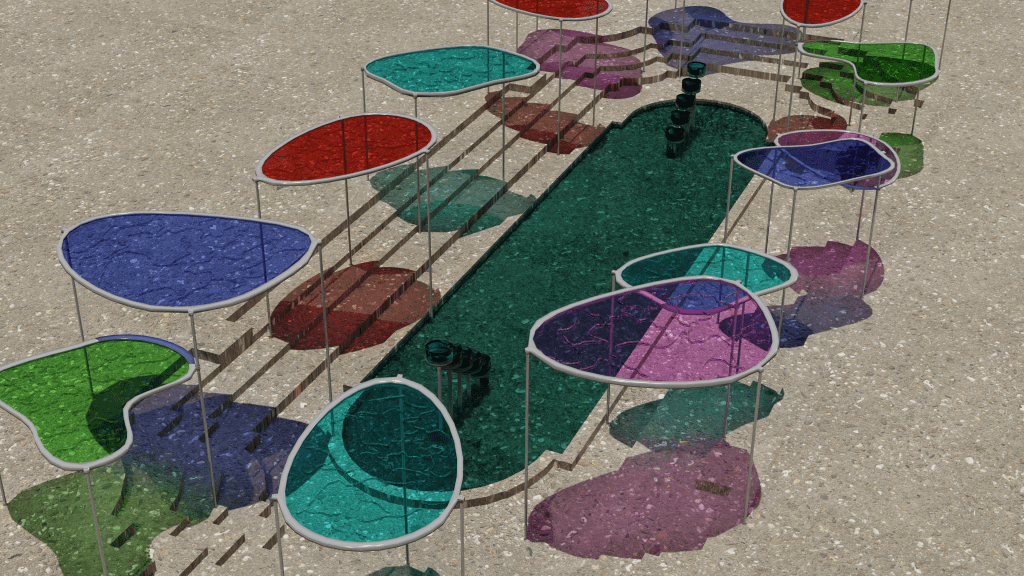

After discussing with Rafik about my proposal I am leaning towards my own design of the coloured glass shelter cause initially I was going with plain coloured glass but then I realized that it looked too plain as the shelter itself was already horizontally flat I figured that adding designs onto the glass would balance this idea out

Developing process so far:

Before

After

Changes:

Support poles

Thickness

Textures

Pond

Layout

Curved edges

Design ideas

Plain

Outwards

Inwards

Plain

Outwards

Inwards

Experimenting with the surfaces

If I were to create a wave surface pattern on each shelter it would look like this

HOW IS CURVED GLASS MADE?

Curved glass is used in a wide range of contemporary applications. Whether it’s a curved glass balcony, a piece of curved glass furniture, a glass partition, a glass canopy or even a curved window, using curved glass adds a wonderful and visually-appealing extra dimension to a design.

But have you ever wondered exactly how curved glass is made?

The basic process of curved glass

All curved glass starts life as normal, flat plate glass. The process to turn it into curved glass is both highly specialised and time-consuming, hence curved glass can often carry a much higher price tag than flat glass.

Before the process can begin, precise measurements are needed for the particular job. A steel mould is constructed according to these measurements, shaped to the curve radius and dimensions of the end product.

The flat glass is then cut to size, and must be thoroughly cleaned and polished. Any rogue particles of dust or dirt could cause the glass to shatter during the bending process, so to ensure it is absolutely clean, a UV light is shone over the glass. This will highlight any small spots of dust that can then be cleaned away.

A mixture of detergent, clay and calcium carbonate is then painted onto the glass. This is to stop the glass sticking to the steel mould during the heating process.

Because steel heats up at a slower rate than glass, the steel mould is pre-warmed to around 480°C. The glass can then be placed on to the mould and loaded into the kiln.

The temperature in the kiln is raised up to 700°C, at which point the bonds between the glass’s silica molecules begin to loosen. This causes the glass to soften and bend, so it can take on the shape of the mould. This shaping can either be achieved through gravity alone, or can be assisted by a mechanical bending press.

The temperature in the kiln must be very carefully controlled at this point, as any variation in temperature across the oven would cause the glass to bend unevenly.

When the glass has fully curved to the mould’s profile, it is gradually and gently cooled over a number of hours. This slow cooling process prevents the curved glass from cracking.

The newly curved glass is then removed from the kiln, ready to be used in whatever application it is destined for.

Types of curved glass

Curved glass is available as standard annealed glass, toughened glass and laminated glass.

If the curved glass is to be toughened, these two processes will be done simultaneously. Instead of reducing the temperature gradually after the bending process, the curved glass will be rapidly super cooled. This tempering process creates the centre tension within the pane of glass that makes it up to five times stronger.

Once glass has been treated in this way it can no longer be cut or drilled, so it can only be produced to order and measurements must be precise.

Laminating is a popular option for curved glass. This process is done after the glass has been curved, where two or more sheets of identical curved glass are sandwiched around a sheet of transparent laminate interlayer, then pressure bonded together. This laminated curved glass can be cut or shaved for a perfect fit, so is frequently the preferred safety glass option.